SSCH160-6000-10000 160kW Industrie-Hydraulikpumpen-Dynamometer-Prüfstand

1. SSCH160-6000-10000 160kW Industrie-Hydraulikpumpen-Dynamometer-Prüfstand – Systemübersicht

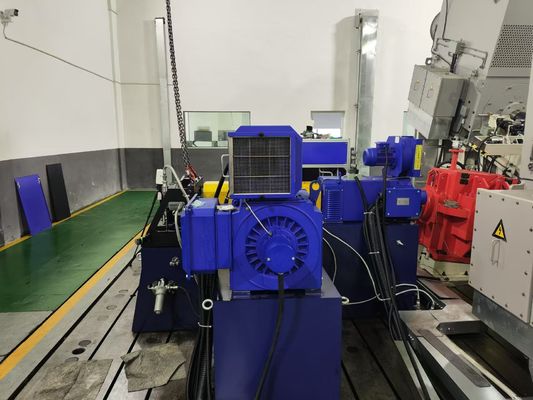

Der Hydraulikpumpen-Dynamometer-Prüfstand SSCH160-6000-10000 wurde speziell für Hochleistungs-Industriehydraulik entwickelt. Er integriert einen 160kW-Elektrodynamometer für hohe Lasten, eine Industrie-Hochdruck-Hydraulikpumpe, ein Mehrfach-Lastmodul und ein industrielles Mess- und Steuerungssystem. Er ermöglicht umfassende Leistungstests von Industrie-Hydraulikpumpen unter Hochdruck (50 MPa), hoher Last (160 kW Dauerlast) und stationären Betriebsbedingungen. Das System unterstützt eine elektrische Energierückgewinnung von über 85 % und eignet sich für Leistungskalibrierung, 1000-Stunden-Dauertests und die Simulation von Fehlern an Hochdruck-Hydraulikpumpen, die in Spritzgussmaschinen, metallurgischen Maschinen und Bergbauausrüstungen eingesetzt werden. Es erfüllt die Anforderungen der Industriehydraulik an hohe Zuverlässigkeit, hohe Last und lange Zyklen.

2. SSCH160-6000-10000 160kW Industrie-Hydraulikpumpen-Dynamometer-Prüfstand – Systemkomponenten

1) Industrie-Hochdruck-Hydraulikpumpe: Nenndruck 50 MPa, Durchflussrate 80 l/min, geeignet für industrielles verschleißfestes Hydrauliköl (z. B. L-HM46/68), mit hoher Langzeitbetriebsstabilität unter Hochdruck, liefert eine kontinuierliche Hochdruckölquelle für das Lastmodul und simuliert die tatsächlichen Ölzufuhrbedingungen von Spritzgussmaschinen und metallurgischen Pressen;

2) Tankmodul: 200 l verfügbares Volumen, Boost-Einstellbereich 0-0,3 MPa (Anpassung an die Druckregelungsanforderungen von Industriepumpen), ausgestattet mit einem dreistufigen Filtersystem (10 μm Genauigkeit), um den Verschleiß der Hydraulikpumpe durch Ölverunreinigungen zu verhindern und die Ölreinheit und Zirkulationsstabilität unter Hochdruckbedingungen zu gewährleisten;

3) 160kW Elektrodynamometer: Die Kernleistungstesteinheit bietet eine stufenlose Drehzahlregelung von 0 bis 10.000 U/min, unterstützt einen 120 %-Überlastbetrieb (kurzzeitige Dauer von 10 Minuten, geeignet für das Anfahren und Abschalten von Industriepumpen mit Stoßbelastungen), steuert das stationäre Drehmoment präzise durch elektromagnetische Kraftbeaufschlagung und testet die Rückgewinnungseffizienz von ≥85 %;

4) Drehmoment- und Drehzahlsensor: Drehmomentbereich 0-500 Nm, Drehzahlbereich 0-10000 U/min, Genauigkeitsklasse ≤0,1 % FS, Echtzeit-Erfassung von Drehmoment- und Drehzahl-Daten von Industrie-Hydraulikpumpen, angepasst an die Anforderungen der stationären Datenerfassung unter hoher Last;

5) Frequenzumrichtersystem: verwendet Direct Torque Control (DTC) mit einer Regelgenauigkeit von ±0,01 Hz; arbeitet in einem Betriebstemperaturbereich von 0 °C bis 45 °C (kompatibel mit Temperaturschwankungen in industriellen Werkstätten), hat einen IP54-Schutzgrad, arbeitet bei 100 % Volllast in Höhen unter 1000 m, hat einen Geräuschpegel von ≤85 dB und unterstützt das Modbus-Kommunikationsprotokoll für industrielle LANs;

6) Lastmodul: Diese Module sind in drei Arten von Industrielasten unterteilt: ① Hochdruck-Überlastventil-Last: Dieses Modul verwendet eine Überlastventilgruppe der 50-MPa-Klasse, um die stationären Druck-Durchfluss-Eigenschaften einer Hydraulikpumpe zu testen; ② Proportionale Drossellast: Dieses Modul verwendet ein Proportionalventil, um die Durchflussänderungen während des Schließens/Öffnens der Form einer Spritzgussmaschine zu simulieren; und ③ Hochleistungs-Lastzylinder: Dieses Modul verwendet einen Hydraulikzylinder der 50-kN-Klasse, um die Hochleistungsbedingungen von metallurgischen Ausrüstungen und Bergbaumaschinen zu simulieren.

7) Mess- und Steuermodul: Integriert eine Mehrkanal-Datenerfassungseinheit (Abtastfrequenz 300 Hz, geeignet für industrielle stationäre Tests), unterstützt die gleichzeitige Erfassung von über 150 Parametern, einschließlich Drehmoment, Druck (0-60 MPa), Durchfluss (0-100 l/min), Öltemperatur, und erzeugt automatisch Pumpenvolumenwirkungsgrad- und Gesamtwirkungsgradkurven sowie Testberichte speziell für Industrieanlagen.

8) Fernbedienungsmodul: Dieses Modul verwendet eine DSP+FPGA-Dual-Core-Architektur, eine X86-Architektur-CPU (1,0 GHz Hauptfrequenz, 1 GB Speicher, 8 GB DOM-Festplatte) und ist mit dem Win10 IoT Industrial Edition-System vorinstalliert. Es unterstützt die Anbindung an das MES-System der Werkstatt und kann eine lokale/Fernbedienung innerhalb von 500 m erreichen, um den Anforderungen unbemannter Industriewerkstätten gerecht zu werden.

3. 160kW Industrie-Hydraulikpumpen-Dynamometer-Prüfstand – Technische Parameter

| Parameter |

Technische Indikatoren |

Parameter |

Technische Indikatoren |

| Nennleistung |

160kW |

Konstanter Drehmoment-Drehzahlbereich |

0-6000 U/min |

| Maximale Ausgangsdrehzahl |

10000 U/min |

Konstanter Leistungsdrehzahlbereich |

6000-10000 U/min |

| Überlastfähigkeit |

120 % (kurzzeitige Dauer von 10 Minuten) |

Nenndrehmoment |

255 Nm |

| Drehmessbereich |

0-500 Nm (adaptiver Sensor) |

Energierückgewinnungseffizienz |

≥85 % (Netzrückspeisung) |

| Drehzahlerfassungsgenauigkeit |

±0,01 % FS |

Kühlmethode |

Zwangswasserkühlung + unabhängiger Wärmeableitungskreislauf |

| Steuerungsmethode |

Drehmoment-/Drehzahl-/Leistungs-Dreifach-Regelkreis-Regelung |

Adapter-Stromversorgung |

380 V ±10 % Dreiphasig 50 Hz (unabhängiger Transformator erforderlich) |

| Stationäre Regelgenauigkeit |

Drehmoment ±0,2 % FS, Drehzahl ±0,1 U/min |

Anwendbarer Hydraulikpumpen-Leistungsbereich |

80-200 kW (Abdeckung von Mainstream-Industriepumpen mittlerer und großer Leistung) |

4. SSCH160-6000-10000 160kW Industrie-Hydraulikpumpen-Dynamometer – Referenzstandards

Nationale Standards

1) GB/T 3766-2021 Allgemeine Regeln und Sicherheitsanforderungen für hydraulische Übertragungssysteme und deren Komponenten

2) GB/T 17487-2021 Hydraulikpumpen-Testmethoden

3) GB/T 23537-2017 Hydraulik-Kolbenpumpe (Sonderstandard für industrielle Hochdruck-Kolbenpumpen)

4) JB/T 7039-2016 "Grenzwerte der Geräuschwerte für Hydraulikpumpen" (Geräuschkonformitätsanforderungen für industrielle Werkstätten)

Internationale Standards

1) ISO 4413:2010 "Fluidtechnik - Allgemeine Regeln und Sicherheitsanforderungen für Systeme und deren Komponenten"

2) ISO 10770-1:2019 "Fluidtechnik - Pumpen und Motoren - Teil 1: Nenndrücke, Nennverdrängungen und Nenndrehzahlen" (Industriepumpen-Nennparameterstandard)

3) DIN 24313:2019 Fluidtechnik - Prüfverfahren für Pumpen

4) ISO 9906:2012 "Hubkolben-Verbrennungsmotoren - Leistung" (geeignet für die Leistungsprüfung von Industriepumpen-Antriebsmotoren)

5. SSCH160-6000-10000 160kW Industrie-Hydraulikpumpen-Dynamometer-Prüfstand – Kernvorteile

1) Hochlast-Stationär-Testfähigkeit: Der 160-kW-Dynamometer unterstützt den stationären Betrieb von 0-10.000 U/min mit einer Drehmomentregelgenauigkeit von ±0,2 % FS. Er kann 72 Stunden lang ununterbrochen 50 MPa-Hochdruck-Stationärtests von Industrie-Hydraulikpumpen durchführen und passt sich der Simulation der Betriebsbedingung "24-Stunden-Dauerbetrieb" von Spritzgussmaschinenpumpen an.

2) Tiefe Anpassung an industriellen Hochdruck: Hydraulikpumpe der 50-MPa-Klasse + Hochdruck-Überlastventilgruppe, die die Testanforderungen von Mainstream-Industrie-Hochdruck-Plungerpumpe (35-70 MPa) abdeckt, kann den Volumenwirkungsgrad-Abnahmetrend der Pumpe unter hohem Druck genau erfassen und bietet Datenunterstützung für die Auswahl von Hydrauliksystemen für Industrieanlagen;

3) Energieeinsparung und Kostenvorteile: Mit einer Energierückspeiseeffizienz von über 85 % gewinnt das System bei einer Volllast von 160 kW etwa 136 kWh Strom pro Stunde zurück, wodurch im Vergleich zu herkömmlichen Widerstandslast-Prüfständen über 60 % der jährlichen Energiekosten eingespart werden. Es eignet sich besonders für die Chargenqualitätsprüfung und die Langzeit-Haltbarkeitstests von Industriepumpen.

4) Mehrfache industrielle Arbeitsbedingungssimulation: Das Lastmodul unterstützt drei Modi: Hochdruck-Überlauf (metallurgisches Pressen), proportionale Drosselung (Spritzgussklemmen) und Hochlastbelastung (Bergbauheben). Pumpenleistungstests in verschiedenen industriellen Szenarien können ohne Geräteänderung durchgeführt werden.

5) Anpassungsfähigkeit an industrielle Werkstätten: Das Frequenzumrichtersystem verfügt über einen IP54-Schutz und eine Zwangswasserkühlung, wodurch es sich an die staubigen und temperaturschwankenden Umgebungen industrieller Werkstätten anpassen kann. Es unterstützt auch die Modbus-Protokollintegration mit dem MES-System der Werkstatt, wodurch die Verknüpfung von Testdaten mit dem Produktionsmanagementsystem ermöglicht wird.

6) Hochzuverlässiges Design: Die Kernkomponenten des Dynamometers bestehen aus industriellen, langlebigen Materialien (wie SKF-Industrie-Hochleistungs-Serienlager), mit einer jährlichen Wartungszeit von ≤30 Stunden; das dreistufige Öltankfiltersystem reduziert den Verschleiß der Hydraulikpumpe und verlängert die Lebensdauer der Testausrüstung.

6. SSCH160-6000-10000 160kW Industrie-Hydraulikpumpen-Dynamometer – Systemanwendungen

1) Hochleistungs-Spritzgussmaschinen-Hydraulikpumpen-Tests: Ziel sind 35-50 MPa-Hochdruck-Plungerpumpe in Spritzgussmaschinen. Dieser Test misst die Druck-Durchfluss-Eigenschaften und den Volumenwirkungsgrad unter Formschließ-/Einspritzbedingungen, um die Formstabilität von Spritzgussprodukten zu gewährleisten.

2) Verifizierung des metallurgischen Maschinen-Hydrauliksystems: Passt sich an 40-60 MPa-Hydraulikpumpen an, die in metallurgischen Pressen und Walzwerken eingesetzt werden, simuliert Hochtemperatur- und Hochlastbedingungen und verifiziert die Hochdruck-, Langzeitbetriebszuverlässigkeit und Fehlerwarnfähigkeiten der Pumpe;

3) Qualitätsprüfung von Bergbaumaschinen-Hydraulikpumpen: Bietet eine werkseitige Leistungskalibrierung für die Hydraulik-Hauptpumpen (30-50 MPa) von Bergbau-Baggern und -Ladern, testet lastabhängige Steuerungs- und Anti-Verschmutzungsfähigkeiten und gewährleistet die Geräteverfügbarkeit in rauen Bergbauumgebungen;

4) Tests von Schiffsdeckmaschinen: Für 30-40 MPa-Hydraulikpumpen, die in Schiffsankerwinden und Winden eingesetzt werden, werden die Drehmomentausgabe und der Wirkungsgrad unter niedrigen Drehzahlen und Hochlastbedingungen getestet, um die Zuverlässigkeitsanforderungen der Schiffbauindustrie zu erfüllen;

5) Forschung und Entwicklung und Verbesserung von Industrie-Hydraulikpumpen: Bietet Forschung und Entwicklung und Tests von 80-200 kW-Pumpen mittlerer und großer Leistung für Hydraulikpumpenhersteller, optimiert die Hochdruck-Dichtungsstruktur und das Verteilerplatten-Design der Pumpe und erhöht die Wettbewerbsfähigkeit der Produkte.

7. Industrie-Hydraulikpumpen-Dynamometer-Prüfstand – Modellliste

| Modell |

Kernkonfiguration (Elektrodynamometer) |

Maximale Testdrehzahl |

Anpassung des Hydraulikpumpendrucks |

| SSCH11-15000-35000 |

11 kW, 7 Nm |

35000 U/min |

≤30 MPa |

| SSCH22-15000-30000 |

22 kW, 14 Nm |

30000 U/min |

≤35 MPa |

| SSCH37-15000-25000 |

37 kW, 24 Nm |

25000 U/min |

≤40 MPa |

| SSCH55-15000-20000 |

55 kW, 35 Nm |

20000 U/min |

≤50 MPa |

| SSCH80-6000-15000 |

80 kW, 127 Nm |

15000 U/min |

≤40 MPa |

| SSCH110-6000-12000 |

110 kW, 175 Nm |

12000 U/min |

≤45 MPa |

| SSCH160-6000-10000 |

160 kW, 255Nm |

10000 U/min |

≤50 MPa |

| SSCH220-6000-8000 |

220 kW, 350 Nm |

8000 U/min |

≤60 MPa |

| SSCH315-3000-6000 |

315 kW, 501 Nm |

6000 U/min |

≤70 MPa |

| Bemerkung |

Unterstützung der Anpassung von Leistung, Drehzahl und Lastmodulen nach Kundenbedürfnissen (z. B. Hinzufügen einer Hochtemperatur-Umgebungskammer und eines Anti-Verschmutzungs-Testmoduls) |

A: Wir unterstützen eine kleine Probebestellung von 1 Stück für Lagerprodukte.

A: Bitte hinterlassen Sie Ihre E-Mail-Adresse, und wir senden Ihnen Ihr elektronisches Musterbuch.

A: Normalerweise 40 % T/T-Anzahlung, vollständige Zahlung vor dem Versand.

A: Der Produktionszyklus für Dynamometer beträgt 6-8 Wochen, der Produktionszyklus für Sensoren beträgt 2-3 Wochen, bei anderen Produkten wenden Sie sich bitte an uns.

A: Hinterlassen Sie uns Ihre E-Mail-Adresse, unsere technischen Mitarbeiter werden sich mit Ihnen über den detaillierten Plan in Verbindung setzen.

A: Sicher, Sie sind jederzeit herzlich willkommen, uns zu besuchen.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!